Rendered at (server): 2026-02-21T23:52:38.281Z

Redefining Industrial Resilience: How AI Infrastructure Delivers Adaptive Advantage

4 August, 2025

Key Takeaways:

- AI for infrastructure transforms static systems into adaptive engines of operational intelligence.

- Strategic value lies in orchestrating the full intelligence stack, not deploying isolated tools.

- Early adopters report up to 3x productivity, 99% fewer defects, and 30% lower energy use with intelligent infrastructure.

- Enterprises that mature visual, physical, and autonomous layers will compound competitive advantage.

- Infrastructure that learns will define the next industrial benchmark, laggards risk 20% revenue loss from quality failures alone.

Industrial enterprises are witnessing the emergence of a fundamentally new operating paradigm where AI for infrastructure transforms from passive assets into active, intelligent systems that sense, learn, and autonomously optimize across operational boundaries.

This shift moves beyond traditional automation, where machines execute predetermined sequences, toward adaptive, intelligent infrastructure that continuously reconfigure itself based on real-time conditions, predictive insights, and strategic objectives.

However, as enterprises rush to implement infrastructure intelligence solutions, they must grapple with a foundational reality:

Incremental AI deployment cannot deliver transformational competitive advantage.

The ability to orchestrate intelligent infrastructure systems into coherent operational ecosystems will determine sustainable competitive advantage.

This analysis explores how industrial leaders turn infrastructure intelligence into strategic advantage by architectural four-layer AI stack that scales with complexity and ambition.

Why AI for Infrastructure Matters Now?

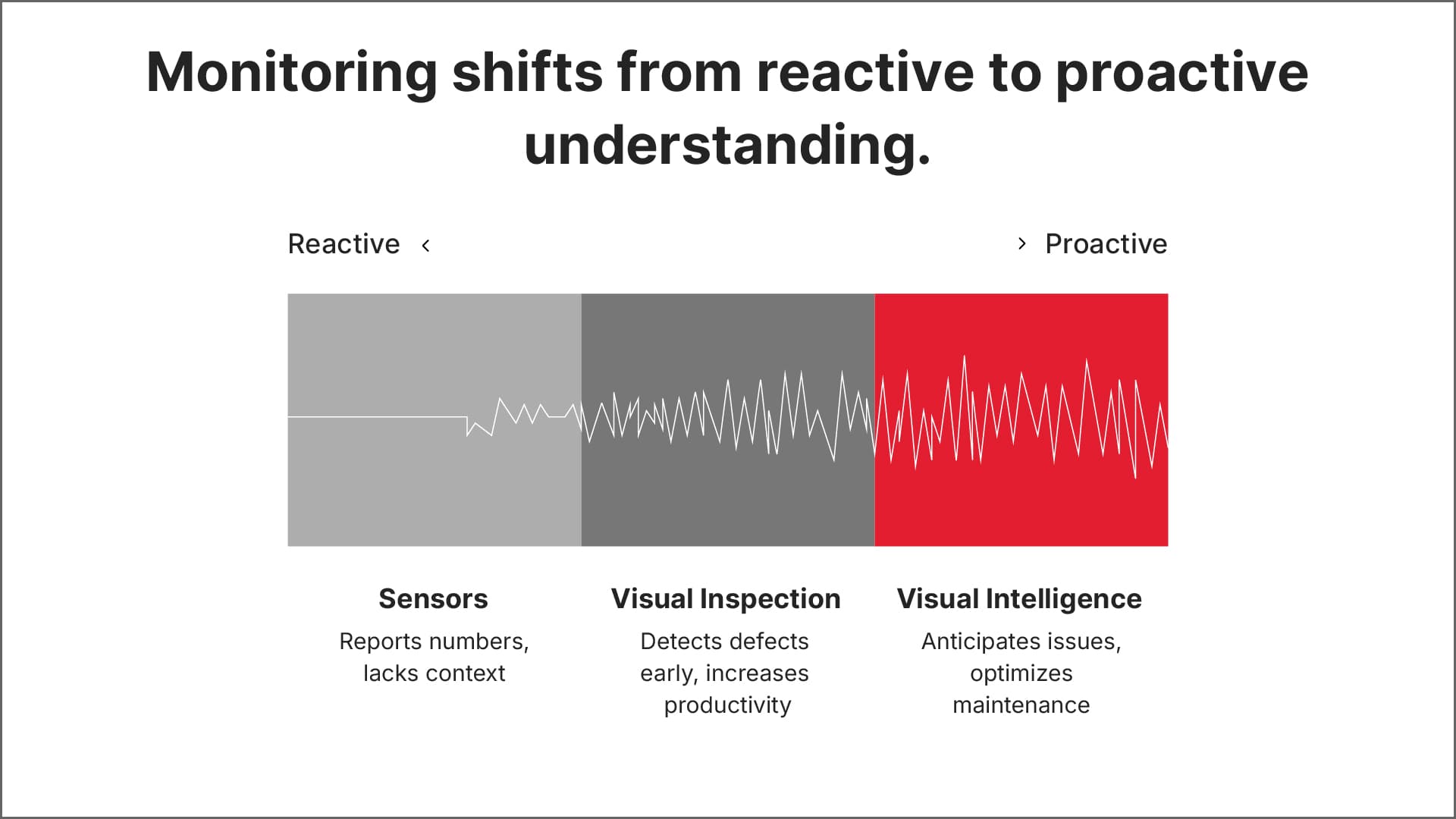

Traditional industrial monitoring has trapped enterprises in a fundamental paradox: the more sensors they deploy, the less they actually understand about what's happening in their operations.

AI for infrastructure addresses this paradox through computer vision: machines that not only detect but also comprehend. This transforms operational intelligence from reactive measurement to proactive comprehension.

When infrastructure powered by AI develops visual intelligence, it operates continuously, contextually, and at a scale no human can match.

These systems recognize degradation patterns, correlate symptoms with performance data, and identify failure indicators in real time, developing something close to operational intuition.

Enterprises still optimizing static systems will be outpaced by infrastructure that learns.

These advantages reflect the strategic shift toward AI for infrastructure as a value engine rather than a monitoring layer.

Computer Vision: The ROI of Cognitive Infrastructure

The economic reality is that traditional quality control catches problems after they occur, when defects have already consumed materials, energy, and labor.

AI-powered visual inspection systems achieve detection rates exceeding 90% while simultaneously increasing productivity by up to 50% (McKinsey, 2022).

In manufacturing environments where quality defects can consume nearly 20% of revenue through scrap, rework, and warranty claims (American Society of Quality), even marginal improvements in early detection translate to massive operational savings and margin protection.

But the strategic value transcends cost avoidance. Infrastructure equipped with visual intelligence operates fundamentally differently.

Instead of relying on scheduled maintenance based on arbitrary intervals, intelligent systems shift to condition-based optimization, which is triggered by actual visual indicators of equipment health.

This transformation represents a structural shift toward infrastructure that anticipates rather than reacts, a hallmark of true AI for infrastructure maturity.

Read more: Manufacturing 5.0: Shaping the Future with Autonomous Agents

Real Results from Early Adopters of AI for Infrastructure

The transformation from reactive to intelligent infrastructure is reshaping competitive dynamics across global industrial operations.

McKinsey’s latest analysis of Lighthouse factories, nearly 60% of breakthrough innovations are now driven by AI, up from just 20% a few years ago.

Leading implementations report:

- 2–3x productivity increases

- 99% reduction in product defects

- 50% higher service levels

- 30% lower energy consumption.

These metrics underscore the economic and operational impact of deploying infrastructure intelligence solutions at scale. (McKinsey, 2024).

AI for Infrastructure in Action: Global Leaders Set the Pace

CITIC Pacific Special Steel in China demonstrated how AI for infrastructure scales production gains. They used AI to analyze real-time blast furnace conditions, boosting throughput by 15% while cutting energy usage by 11%.

Meanwhile, Agilent Technologies in Germany transformed its vision AI into a standardized toolkit, rolling out five distinct use cases that led to a 49% defect reduction in just four months (McKinsey, 2024).

At Mondelēz’s Beijing facility, frontline workers no longer operate machines; they guide them. The infrastructure intelligence solutions enabled:

- 2x productivity

- 70% less waste

- Up to 25% energy savings

"Enterprises that move first will compound gains. Those that wait will compound costs."

Read more: Technological Leap: Innovations Through the Ages

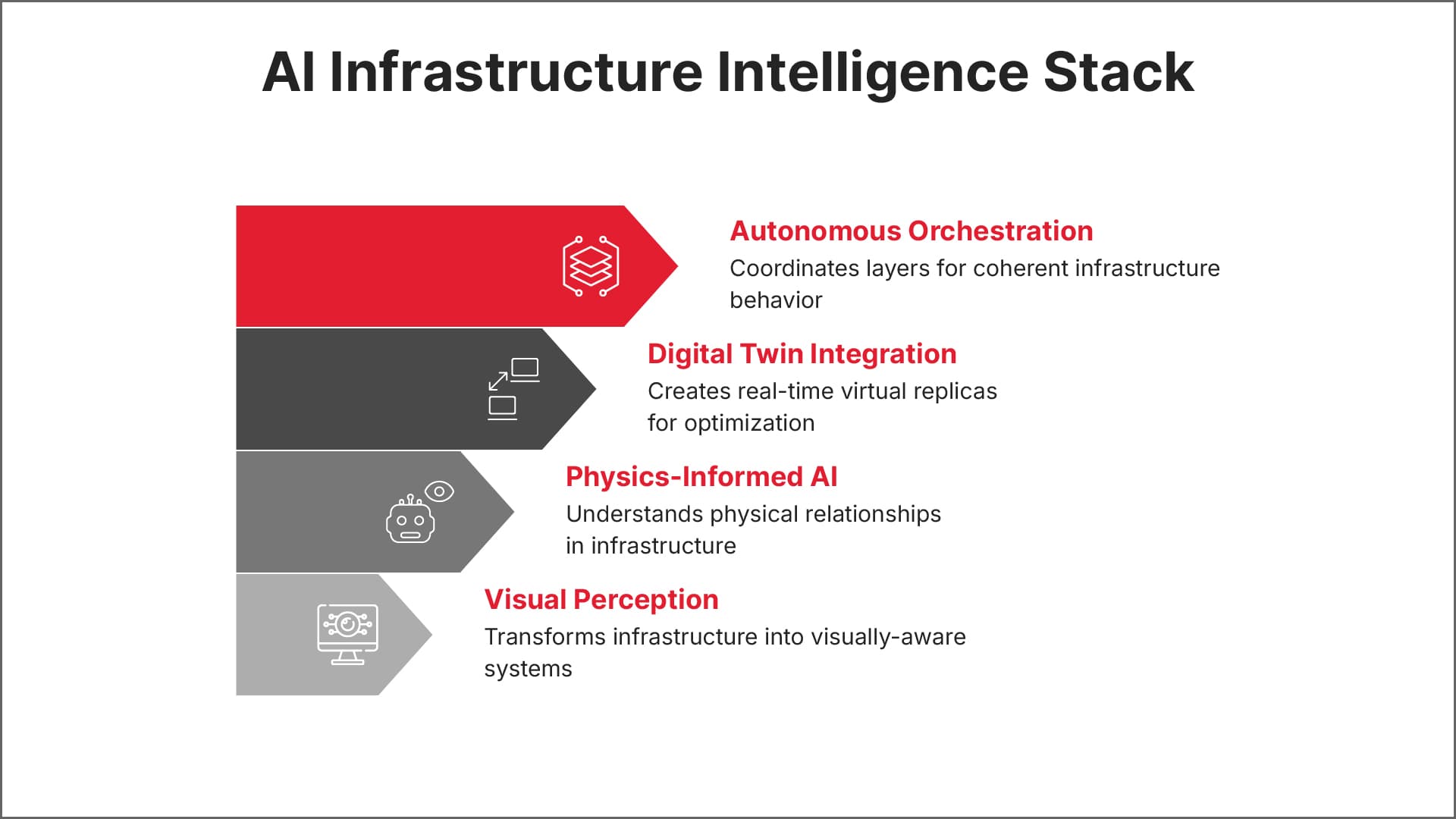

The Four-Layer AI Infrastructure Intelligence Stack

The journey from automation to AI for infrastructure excellence is powered by an integrated intelligence architecture.

At the core of every high-functioning intelligent infrastructure system lies a four-layer AI stack. Each layer unlocks specific capabilities, but together they create a self-learning, self-optimizing operational engine.

" It’s not the AI models you deploy; rather, it’s the intelligence architecture you design that determines long-term advantage."

Layer 1: Visual Perception Intelligence

This layer transforms traditional systems into AI-powered infrastructure that can interpret, analyze, and act on visual signals.

Modern vision AI combines:

- Thermal imaging

- Hyperspectral analysis

- 3D depth sensing

Resulting in machines that detect subtle indicators of wear, safety risks, and performance drifting, long before traditional sensors respond.

Layer 2: Physics-Informed AI Models

Visual data alone can’t explain why something is happening.

This layer introduces reasoning, fusing vision with physical principles to enable AI for infrastructure systems to understand and anticipate behavior.

When visual anomalies appear, physics-informed AI anticipates performance impacts.

Layer 3: Digital Twin AI Integration

This is where infrastructure gains foresight.

AI-powered digital twins continuously ingest real-world data to simulate operational outcomes before physical execution.

This enables infrastructure intelligence solutions to test, learn, and optimize virtually before acting in the physical environment.

Layer 4: Autonomous Orchestration AI

The final layer coordinates real-time decisions across vision systems, digital twins, and physics-informed models.

This is where AI for infrastructure becomes self-directing, continuously optimizing through autonomous agents that learn and improve over time.

" Only when stacked intelligently do these layers unlock capabilities that scale with operational complexity and strategic ambition. "

Download our whitepaperAgentic AI: The Future of Autonomous Enterprise to explore how AI infrastructure drives resilience and efficiency across industrial operations.

From Sensing to Strategy: What AI-First Infrastructure Can Do?

When the four-layer intelligence stack functions in harmony, AI for infrastructure becomes a strategic operating system that sees, learns, adapts, and acts.

These capabilities signal a new model of industrial operations. Here’s what becomes possible:

Predictive Visual Maintenance

AI-powered computer vision continuously monitors asset health, detecting bearing wear, corrosion, and mechanical fatigue long before traditional sensors register abnormalities.

This turns maintenance from a scheduled reaction into visual foresight.

Real-Time Quality Optimization

Computer vision AI that not only detects quality issues but also learns and improves, embodying the principles of Agentic AI and co-creation that power modern industrial agility.

It autonomously adjusts process parameters to prevent defects before they occur.

The result is closed-loop quality control and zero-defect manufacturing.

Intelligent Resource Allocation

Vision-enabled AI tracks inventory, usage patterns, and asset behavior across systems, enabling just-in-time operations, waste reduction, and smarter capital asset utilization through real-time, context-aware allocation decisions.

Adaptive Safety Systems

Computer vision AI continuously monitors for unsafe human behavior, equipment malfunctions, and environmental hazards, triggering alerts or automated interventions before incidents occur.

How to Scale AI Infrastructure Maturity?

The challenge for industrial leaders is how to architect the transformation. In a landscape where infrastructure itself is becoming intelligent, the sequence of investment decisions will determine whether AI becomes a tactical tool or a core source of enterprise advantage.

Aligning your AI roadmap with operational maturity ensures your infrastructure intelligence solutions deliver both short-term ROI and long-term resilience.

Foundation Phase: Prioritize Visual Intelligence

Enterprises initiating AI infrastructure transformation need to start where ROI is immediate.

Deploy computer vision in high-impact monitoring use cases where human inspection creates bottlenecks or safety risks.

This builds the institutional muscle for managing intelligent visual systems.

Integration Phase: Add Physics-Informed Reasoning

Mature enterprises should invest in physics-informed AI models that merge visual intelligence with understanding, enabling predictive capabilities that explain not just what is happening visually, but why.

Together, vision and physics form the foundation for anticipatory operations

Optimization Phase: Orchestrate the Stack

Mature enterprises can implement comprehensive AI orchestration systems that coordinate all four layers into unified autonomous optimization capabilities. This represents the transition from assisted decision-making to autonomous operational management.

Innovation Phase: Compound Competitive Advantage

Enterprises with mature implementations can now build infrastructure powered by AI that opens new frontiers.

Use all four layers to create capabilities competitors can't match—intelligent energy optimization, dynamic logistics, or fully adaptive production lines that redefine operational possibilities.

Leading enterprises must explore applications that combine all intelligence layers to create entirely new operational capabilities. These often require advanced design patterns and systems thinking delivered through AI development services.

Conclusion

The emergence of AI for infrastructure marks a structural transformation in industrial competition.

Sustainable advantage accrues to enterprises that treat infrastructure intelligence as a core institutional capability, embedding systems that scale with operational complexity.

As intelligent infrastructure shapes production efficiency, quality outcomes, and operational resilience, the gap between learning systems and static automation will define market outcomes. In this new industrial paradigm, AI for infrastructure is foundational to competitive relevance and long-range operational sovereignty.

At CodeNinja, we help enterprises operationalize AI for infrastructure through domain-tuned implementations designed for reliability, scalability, and enterprise-grade performance. Our AI Infrastructure solutions ensure that intelligence is deployed with accountability, aligning autonomous optimization with operational goals, safety requirements, and long-term strategic intent.