Manufacturing 5.0: Shaping the Future with Autonomous Agents

6 February, 2025

Agentic AI in Manufacturing Industry

Summary:

Manufacturing faces a critical evolution gap. While 89% of companies plan AI implementation, many still rely on basic automation instead of autonomous AI.

Agentic AI in manufacturing bridges this divide by deploying self-learning AI agents that make real-time decisions without human intervention. Early adopters achieve 15% productivity gains, 20% inventory reductions, and 10% supply chain cost savings.

These intelligent systems transform production efficiency, quality control, and supply chain synchronization, positioning manufacturers for Industry 5.0 leadership while competitors struggle with outdated automation.

Key Takeaways:

- Agentic AI in manufacturing enables autonomous decision-making, reducing downtime through predictive maintenance and real-time optimization

- Early adopters achieve 10-20% inventory reduction and 5-10% supply chain cost savings through AI-powered planning.

- Autonomous agents in manufacturing excel in three critical areas: production efficiency, quality control compliance, and supply chain synchronization

- 83% of electronics manufacturers already use AI, with energy (72%) and process industries (68%) following closely

- Implementation requires strategic process integration, organizational restructuring, and intelligent deployment of existing infrastructure

As we move toward an autonomous future powered by artificial intelligence systems, a new era of industrial transformation is unfolding. Industry 5.0 heralds the promise of Artificial General Intelligence (AGI), yet its foundation is firmly rooted in automation, predictive intelligence, and adaptive decision-making. With Agentic AI we are already seeing some early real-world applications, businesses are leveraging the computational power of these systems to build process and decision-making agility to drive operational excellence. With 89% of companies planning to implement AI in their production networks (Boston Consulting Group 2025) and 78% of manufacturers already integrating autonomous AI into their corporate strategies (Manufacturing Leadership Council 2024), the manufacturing sector is entering a pivotal phase of its digital evolution.

AI-powered systems are transforming workflows, enabling predictive maintenance, real-time data analysis, and smarter supply chain management. These intelligent systems are already delivering measurable results, with manufacturers using AI tools seeing up to a 15% boost in productivity (McKinsey 2023).

Among these innovations, autonomous AI agents stand out as a powerful tool for maintaining a competitive edge in a rapidly evolving market. With 68% of companies already implementing AI solutions (Boston Consulting Group 2025), manufacturers who fail to harness these technologies risk falling behind, as more agile competitors capitalize on the power of intelligent automation.

What is the Role of Agentic AI in Manufacturing Operations?

Manufacturing has always been at the forefront of technological adoption, from the early use of robotics to the integration of AI-driven systems. Toyota’s Kaizen philosophy, which emphasizes continuous improvement, is a prime example of how operational efficiency has long been central to success (Toyota 2024). As we enter the age of industrialization, the role of AI in manufacturing is expanding from simple automation to more advanced, autonomous systems that enable real-time decision-making and enhanced collaboration (Forbes 2022).

Historically, AI in manufacturing focused on automation and predictive maintenance. Systems were designed to predict machine failures or optimize production schedules. Agentic AI in manufacturing take this transformative potential further by offering self-learning, autonomous decision-making capabilities.

These agents not only interact with their environment but also execute tasks without human intervention. The result is a new level of efficiency and precision, with autonomous AI agents capable of transforming industrial operations. (World Economic Forum 2025).

How Is AI Adoption Transforming Manufacturing Sectors?

Looking across industries, electronics and technology equipment lead the way with 83% AI adoption, followed by energy at 72% and process industries at 68%, demonstrating the significant momentum AI is gaining in various sectors.

Beyond productivity, many executives also view AI as promoting substantial opportunities for sustainability (53%), production flexibility (52%), and workforce support (47%), highlighting its broader strategic impact in manufacturing. (World Economic Forum 2023) Early adopters have already seen up to 14% savings (Boston Consulting Group 2025), and as Agentic AI advances from assistance to true autonomy, it redefines industrial automation, unlocking significant opportunities for growth and innovation.

What Are the Key Agentic AI Use Cases in Manufacturing?

1: AI-Powered Production Efficiency in Manufacturing

To optimize production efficiency, Agentic AI in manufacturing industry can automate critical processes such as monitoring production metrics in real-time, predicting equipment failures, and optimizing resource distribution. By integrating AI with IoT systems, manufacturers can identify operational inefficiencies, minimize downtime, and improve resource utilization.

In the use case above, autonomous agents analyze real-time production metrics, machine performance, and resource utilization to pinpoint inefficiencies or production bottlenecks. For instance, agents can automatically schedule maintenance when equipment shows signs of under-performance or reallocate resources based on fluctuating demand.

Another key action involves optimizing production schedules to reduce downtime, ensuring maximum output alignment. With the ability to autonomously adjust processes, Agentic AI empowers manufacturers to streamline operations, improve throughput, and reduce costs, driving precision and ensuring long-term operational success.

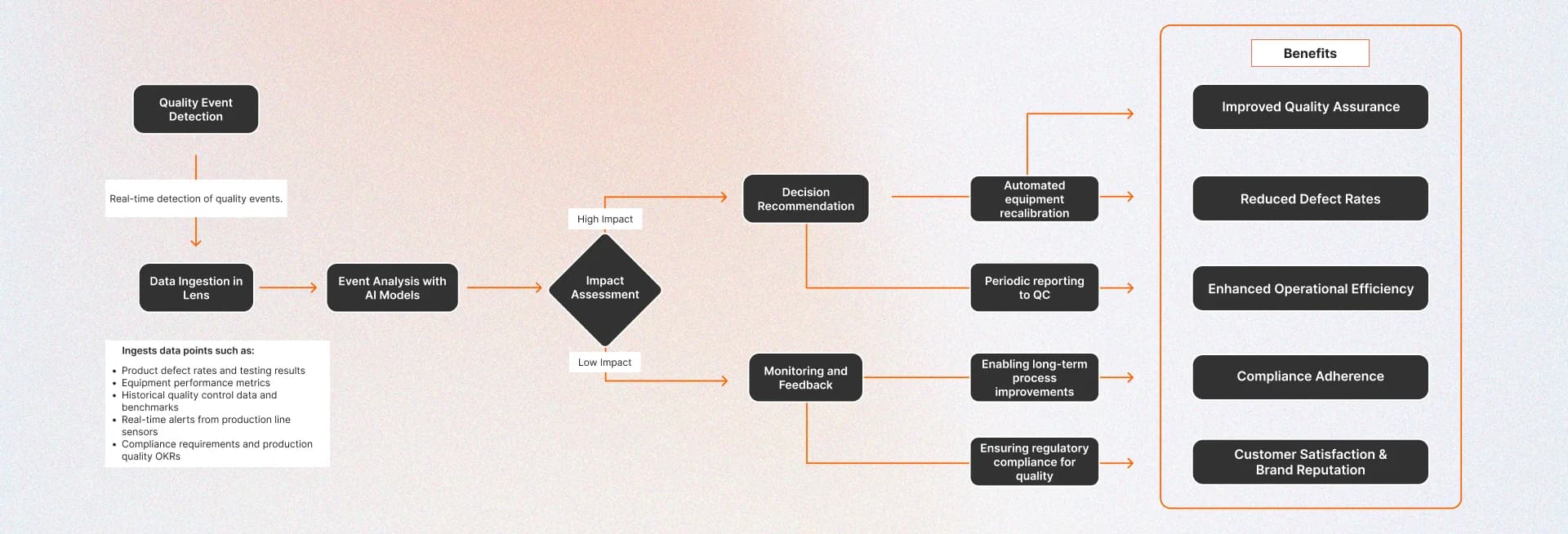

2: Ensuring Compliance with Intelligent Systems

Ensuring quality control compliance is crucial for regulatory adherence, and brand reputation. Autonomous AI agents transform this process by using real-time data, predictive analytics, and autonomous decision-making to optimize quality, reduce defects, and ensure continuous compliance.

To help establish the scalability and impact of Agentic AI in quality control, we’ve outlined a basic use case for manufacturing. By deploying autonomous agents, real-time data from production lines, sensors, and customer feedback can be utilized to ensure consistent quality standards. In a scenario where there are fluctuations in production processes, agents can autonomously identify and address quality deviations while ensuring compliance.

The real power for autonomous agents lies in their ability to learn and predict. Agents analyze both historical and real-time data, forecasting potential failures and identifying trends that might impact quality. For example, if an equipment malfunction is detected, agents can predict its effect on product quality and initiate preventive measures, reducing downtime and maintaining operational efficiency. This proactive approach ensures continuous alignment with regulatory standards, driving long-term success in quality assurance and operational excellence.

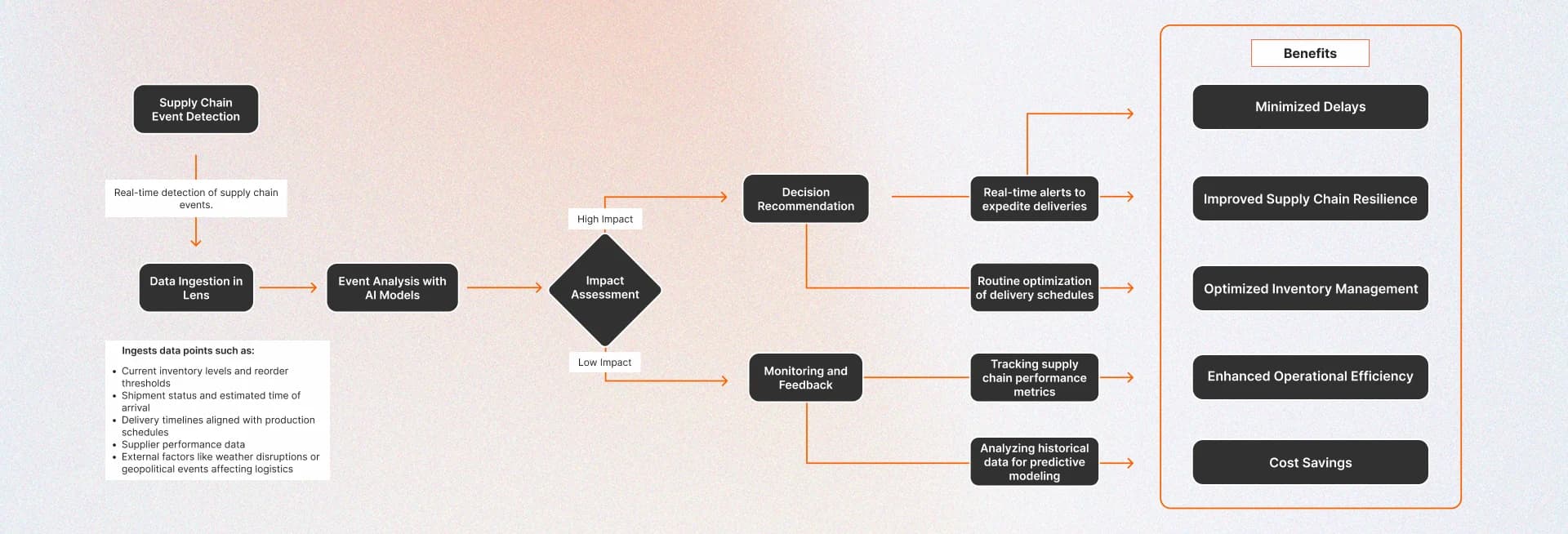

3: Real-Time Supply Chain Synchronization with AI Agents

AI is set to revolutionize supply chain operations, with early adopters achieving significant improvements. Companies using AI-powered tools have optimized production and inventory planning, reducing inventory by 10-20% and improving planning efficiency. These advancements reduce overall supply chain costs by 5-10%, streamlining operations and freeing up resources to support growth (McKinsey 2022).

In this use case, Agentic AI analyzes key supply chain metrics such as inventory levels, shipment statuses, and supplier performance to detect disruptions in real-time. For example, when faced with potential delays or interruptions in supplier deliveries, AI can autonomously adjust shipment routes or engage backup suppliers to maintain production flow.

Additionally, for more routine issues like minor inventory discrepancies, AI agents can recommend adjustments to ensure alignment with production schedules. By leveraging models like ‘Demand-Driven Supply Networks,’ AI agents can autonomously synchronize inventory levels with production needs, ensuring timely deliveries and reducing stock outs. This proactive approach enhances supply chain efficiency, reduces downtime, and optimizes resource utilization, ultimately improving operational resilience and minimizing costs across manufacturing operations.

How Should Manufacturers Deploy AI Agents?

Implementing autonomous AI in manufacturing requires a comprehensive approach that integrates AI into core processes while maintaining operational continuity. First, manufacturers must streamline processes like production scheduling, inventory management, and supply chain coordination with AI-driven decision-making. By leveraging real-time data and predictive analytics, AI in manufacturing enables the optimization of production flows, reduces downtime, and enhances resource utilization.

Source: McKinsey 2022

.webp&w=1920&q=75)

Rewiring the organization is key; roles such as AI-driven process managers and operational coordinators should be established to ensure alignment across departments. Empowering teams with the necessary AI capabilities and fostering a culture of agility will allow manufacturers to adapt to changing conditions in real-time, ensuring that they stay ahead in the future of agentic AI in manufacturing.

Finally, deploying autonomous AI technologies intelligently, leveraging existing infrastructures while enhancing with advanced predictive capabilities, will unlock competitive strengths while bolstering operational efficiency.

Why Are Intelligent Systems Essential Now?

The manufacturing sector is at a crossroads, where the rapid advancement of autonomous AI is creating new leaders and reshaping competitive dynamics. With a growing reliance on automation and predictive intelligence, companies that embrace Agentic AI in manufacturing today will be positioned to lead tomorrow. For an industry driven by operational efficiency and quality standards, Agentic AI offers a transformative path forward; optimizing production, enhancing supply chain synchronization, and ensuring regulatory compliance.

As early adopters already experience significant gains, including a 15% reduction in logistics costs, a 35% improvement in inventory levels, and a 65% boost in service levels (McKinsey 2021), the gap between industry leaders and challengers continues to narrow.

By leveraging autonomous AI to reduce costs, improve productivity, and drive innovation, manufacturers can create scalable, sustainable advantages. The ability to integrate autonomous agents into core processes while maintaining business continuity enables manufacturers to adapt swiftly to market changes.

At CodeNinja, we recognize the transformative power of agentic AI in manufacturing. Our AI agent development framework Lens offers a transparent, scalable, and secure solution built on open-source principles to empower manufacturers globally. By integrating autonomous AI agents tailored to your specific needs, we ensure your AI systems are future-proof, privacy-compliant, and fully aligned with your strategic objectives.

The question now becomes: will you lead the transformation or be left behind?

Learn More About CodeNinja’s Proprietary Agentic AI Framework

FAQs

Q: Can agentic AI integrate with legacy manufacturing systems and ERP platforms?

Yes, modern agentic AI in manufacturing solutions is designed for compatibility with existing infrastructure. Integration approaches include:

- API-based connections to legacy ERP systems

- IoT sensor overlays for older equipment

- Middleware solutions bridging AI agents with MES platforms

- Gradual phased implementation without disrupting operations

Q: What are the main implementation challenges for agentic AI in manufacturing facilities?

Deploying agentic AI in manufacturing faces several critical hurdles that organizations must address:

- Legacy system integration requiring IoT and infrastructure upgrades

- High initial investment costs

- Data quality issues from siloed, fragmented systems

- Workforce resistance and skills gaps

- Cybersecurity and compliance concerns

Q: Do manufacturers need specialized skills to implement and maintain agentic AI systems?

Yes, deploying agentic AI in manufacturing requires new competencies that many organizations currently lack. Essential skill requirements include:

- AI model development and fine-tuning expertise

- Data engineering for real-time processing pipelines

- System integration capabilities for connecting legacy infrastructure

- AI governance and risk management knowledge

- Human-agent collaboration design skills

.jpg&w=256&q=75)

Zobaria Asma

Asst. Manager Brand & Communications

Zobaria serves as the Asst. Manager Brand & Communications at CodeNinja, driving brand strategy and communication efforts across diverse global markets, including APAC, LATAM, and MENA. With over 5 years of experience in scaling businesses, she brings expertise in SaaS branding and positioning. Her expertise spans a range of sectors, ensuring that CodeNinja's messaging resonates with diverse audiences while reinforcing its leadership in hybrid intelligence, AI-driven innovation, and digital transformation.

Related Insights to Agentic AI

28 January, 2025

Retail 4.0 - Revolutionizing CX through Artificial Intelligence Agents

Struggling with slow customer response times and inefficiencies? Autonomous AI agents streamline support, enabling faster resolutions, proactive servicing, and improved CX.

16 December, 2024

Agentic AI: Shaping Smarter Workforces Through Co-Creation

Explore how autonomous agents drive innovation, boost efficiency, and power smarter decisions through collaborative intelligence.

14 November, 2024

Supercharging Enterprise Innovation with Agentic AI

This blog explores how Agentic AI is revolutionizing industries by enabling autonomous decision-making, driving productivity, and shaping the future of intelligent automation